Successful Case:

MVP Computer Vision System for Automation of Thermoplastic Automatic Machines

The correct end of this phase is the absence of any unnecessary details on the form. The presence of unnecessary elements can be checked by capturing the image at the moment after opening the form and analyzing the obtained image using machine learning methods. In this case, a binary classification problem is solved, the two classes in which are correct phase completion and incorrect phase completion. The K-Nearest Neighbours method has been proposed to be used for classification. This method is computationally efficient, which allows the use of compact computing boards and not to implement a multi-component architecture consisting of separate cameras, computing centers and data transmission network. Thus, the proposed solution to the problem of controlling the correctness of injection molding machine phase termination is based on a computationally efficient machine learning algorithm, which allows designing a solution in a single package.

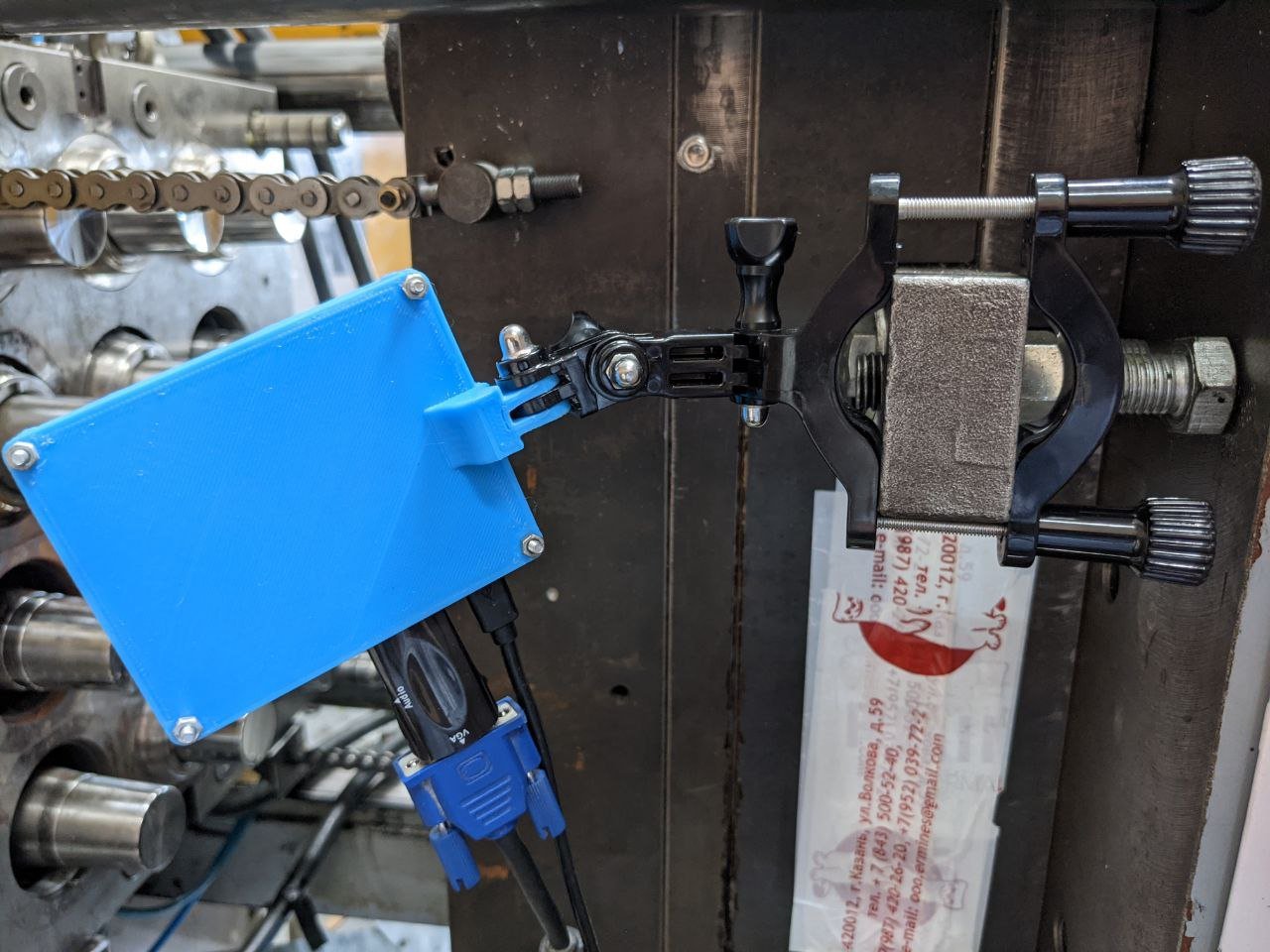

Based on the results, the prototype system was successfully developed and further developed in real production.

Molds of injection molding machines are a product, which in terms of technical requirements can be compared with units and mechanisms of space technology. They are, in essence, the basis of the machine, and the accuracy of their production is measured in microns. In most cases, they have a complex three-dimensional geometric shape and are made of particularly hard metals and alloys, which is why they are so expensive and difficult to produce.

Each injection molding machine is equipped with at least one, but sometimes several molds. The number of molds varies depending on the product range and the company’s production plans.

The purchase of a new mold for a specific injection molding machine and a specific product requires considerable funds even on the scale of a large enterprise.

By installing the system of automatic control of molds and working areas developed by us, the company gets an increase in the life of molds, ensures uninterrupted operation of production, reduces the number of possible defects, thus significantly reducing production costs.

As part of the MVP implementation, a state-of-the-art computer vision and machine learning system was used at that time. Together with the hardware, the proposed system represents a complete and complete solution for controlling the production cycle of a thermoplastic automatic machine. Compared to a small number of competitors, the proposed solution relies on the latest advances in artificial intelligence. Whereas similar solutions use comparison with a static reference image. The use of machine learning technologies in the project allows to control the production process with great accuracy. Also the key feature of the proposed solution is its universality and lack of attachment to a specific model of thermoplastic automatic machine.

The main task of the MVP development was to control the correctness of the stages of the mold casting cycle. The most interesting from the point of view of the production process is the phase after mold opening. Since incorrect completion of this phase entails complete or partial failure of the mold for casting, which entails serious economic consequences for the company.